*Affiliate Disclosure* Posts within this website may contain affiliate links, which means we receive a small percentage if you make a purchase using affiliate links. We only support affiliates we believe have quality products and services for our readers.

Hello all!

Sign up for our newsletters: Everything NEC Exam Prep! Get weekly updates, tips, tutorials and much more.

In case you missed it, here are 5 NEC questions and answers by Mike Holt.

Want more?

For more NEC® practice ORDER Mike Holt’s 2014 NEC® Electrical Exam Preparation & Master (or Journeyman) Contractor Simulated Exam book bundle.

Want to really understand the 2014 NEC®? Get up to speed with Mike Holt’s Code products.

- Designed to make learning easy.

- Detailed instructional graphics to illustrate the concept in real-life situations.

- DVD programs that feature Mike and a panel of industry experts to give you an inside view and in-depth analysis of the Code and how to apply it.

Visit www.TexasElectricalExam.com

By

Mike Holt for EC&M Magazine

Mike Holt for EC&M Magazine

Note:

These questions are based on the 2014 NEC®. Any underlined text indicates a

change to the Code rule for the 2014 NEC.

These questions are based on the 2014 NEC®. Any underlined text indicates a

change to the Code rule for the 2014 NEC.

Q1.

What are the working space requirements for electrical equipment?

What are the working space requirements for electrical equipment?

A1.

For the purpose of safe operation and maintenance of equipment, access and

working space must be provided about all electrical equipment.

For the purpose of safe operation and maintenance of equipment, access and

working space must be provided about all electrical equipment.

Equipment

that may need examination, adjustment, servicing, or maintenance while

energized must have working space provided in accordance with 110.26(A)(1),

(2), and (3):

that may need examination, adjustment, servicing, or maintenance while

energized must have working space provided in accordance with 110.26(A)(1),

(2), and (3):

Author’s

Comment:

Comment:

The

phrase “while energized” is the root of many debates. As always, check with the

AHJ to see what equipment he or she believes needs a clear working space.

phrase “while energized” is the root of many debates. As always, check with the

AHJ to see what equipment he or she believes needs a clear working space.

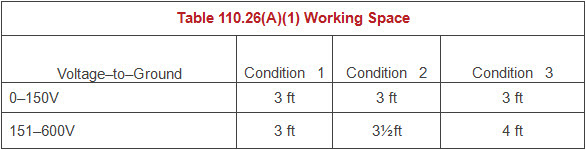

The

working space, which is measured from the enclosure front, must not be less

than the distances contained in Table 110.26(A)(1)

working space, which is measured from the enclosure front, must not be less

than the distances contained in Table 110.26(A)(1)

.

§ Condition 1—Exposed live parts on one side of

the working space and no live or grounded parts, including concrete, brick, or

tile walls are on the other side of the working space.

the working space and no live or grounded parts, including concrete, brick, or

tile walls are on the other side of the working space.

§ Condition 2—Exposed live parts on one side of

the working space and grounded parts, including concrete, brick, or tile walls

are on the other side of the working space.

the working space and grounded parts, including concrete, brick, or tile walls

are on the other side of the working space.

§ Condition 3—Exposed live parts on both sides

of the working space.

of the working space.

Working

space isn’t required for the back or sides of assemblies where all connections

and all renewable or adjustable parts are accessible from the front

[110.26(A)(1)(a)].

space isn’t required for the back or sides of assemblies where all connections

and all renewable or adjustable parts are accessible from the front

[110.26(A)(1)(a)].

If

special permission is granted in accordance with 90.4, working space for

equipment that operates at not more than 30V ac or 60V dc can be less than the

distance in Table 110.26(A)(1) [110.26(A)(1)(b)].

special permission is granted in accordance with 90.4, working space for

equipment that operates at not more than 30V ac or 60V dc can be less than the

distance in Table 110.26(A)(1) [110.26(A)(1)(b)].

Author’s

Comment:

Comment:

See

the definition of “Special Permission” in Article 100.

the definition of “Special Permission” in Article 100.

If

electrical equipment is being replaced, Condition 2 of Table 110.26(A)(1) is

permitted between dead-front switchboards, switchgear, panelboards, or motor control centers located across the aisle

from each other where conditions of maintenance and supervision ensure that

written procedures have been adopted to prohibit equipment on both sides of the

aisle from being open at the same time, and only authorized, qualified persons

will service the installation [110.26(A)(1)(c)].

electrical equipment is being replaced, Condition 2 of Table 110.26(A)(1) is

permitted between dead-front switchboards, switchgear, panelboards, or motor control centers located across the aisle

from each other where conditions of maintenance and supervision ensure that

written procedures have been adopted to prohibit equipment on both sides of the

aisle from being open at the same time, and only authorized, qualified persons

will service the installation [110.26(A)(1)(c)].

Author’s

Comment:

Comment:

The

working space requirements of 110.26 don’t apply to equipment included in

Chapter 8—Communications Circuits [90.3].

working space requirements of 110.26 don’t apply to equipment included in

Chapter 8—Communications Circuits [90.3].

(2)

Width of Working Space. The width of the working space must be a minimum of 30

in., but in no case less than the width of the equipment [110.26(A)(2)].

Width of Working Space. The width of the working space must be a minimum of 30

in., but in no case less than the width of the equipment [110.26(A)(2)].

Author’s

Comment:

Comment:

The

width of the working space can be measured from left-to-right, from right-to-left,

or simply centered on the equipment, and the working space can overlap the

working space for other electrical equipment.

width of the working space can be measured from left-to-right, from right-to-left,

or simply centered on the equipment, and the working space can overlap the

working space for other electrical equipment.

In

all cases, the working space must be of sufficient width, depth, and height to

permit all equipment doors to open 90 degrees.

all cases, the working space must be of sufficient width, depth, and height to

permit all equipment doors to open 90 degrees.

The

height of the working space in front of equipment must not be less than 6½ ft,

measured from the grade, floor, platform, or the equipment height, whichever is

greater [110.26(A)(3)].

height of the working space in front of equipment must not be less than 6½ ft,

measured from the grade, floor, platform, or the equipment height, whichever is

greater [110.26(A)(3)].

Equipment

such as raceways, cables, wireways, cabinets, panels, and so on, can be located

above or below electrical equipment, but must not extend more than 6 in. into

the equipment’s working space.

such as raceways, cables, wireways, cabinets, panels, and so on, can be located

above or below electrical equipment, but must not extend more than 6 in. into

the equipment’s working space.

Ex

1: The minimum headroom requirement doesn’t apply to service equipment or

panelboards rated 200A or less located in an existing dwelling unit.

1: The minimum headroom requirement doesn’t apply to service equipment or

panelboards rated 200A or less located in an existing dwelling unit.

Author’s

Comment:

Comment:

See

the definition of “Dwelling Unit” in Article 100.

the definition of “Dwelling Unit” in Article 100.

Ex

2: Meters are permitted to extend beyond the other equipment.

2: Meters are permitted to extend beyond the other equipment.

The

working space required by this section must be clear at all times. Therefore,

this space isn’t permitted for storage [110.26(B)].

working space required by this section must be clear at all times. Therefore,

this space isn’t permitted for storage [110.26(B)].

When

normally enclosed live parts are exposed for inspection or servicing, the

working space, if in a passageway or general open space, must be suitably

guarded.

normally enclosed live parts are exposed for inspection or servicing, the

working space, if in a passageway or general open space, must be suitably

guarded.

Author’s

Comment:

Comment:

When

working in a passageway, the working space should be guarded from occupants

using it. When working on electrical equipment in a passageway one must be

mindful of a fire alarm evacuation with numerous occupants congregated and

moving through the area.

working in a passageway, the working space should be guarded from occupants

using it. When working on electrical equipment in a passageway one must be

mindful of a fire alarm evacuation with numerous occupants congregated and

moving through the area.

CAUTION:

It’s very dangerous to service energized parts in the first place, and it’s

unacceptable to be subjected to additional dangers by working around bicycles,

boxes, crates, appliances, and other impediments.

It’s very dangerous to service energized parts in the first place, and it’s

unacceptable to be subjected to additional dangers by working around bicycles,

boxes, crates, appliances, and other impediments.

Author’s

Comment:

Comment:

Signaling

and communications equipment must not be installed in a manner that encroaches

on the working space of the electrical equipment.

and communications equipment must not be installed in a manner that encroaches

on the working space of the electrical equipment.

Q2.

What are the rules related to the installation of conductors from different

voltage systems, such as 120V, 208V, 240V, 277V, and 480V in the same raceway

or enclosure?

What are the rules related to the installation of conductors from different

voltage systems, such as 120V, 208V, 240V, 277V, and 480V in the same raceway

or enclosure?

A2.

If the premises wiring system contains branch circuits supplied from more than

one voltage system, each ungrounded conductor must be identified by phase and

system at all termination, connection, and splice points in accordance with 210.5(C)(1)(a) and (b) [210.5(C)(1)].

If the premises wiring system contains branch circuits supplied from more than

one voltage system, each ungrounded conductor must be identified by phase and

system at all termination, connection, and splice points in accordance with 210.5(C)(1)(a) and (b) [210.5(C)(1)].

Identification

can be by color coding, marking tape, tagging, or other means approved by the

authority having jurisdiction [210.5(C)(1)(a)].

can be by color coding, marking tape, tagging, or other means approved by the

authority having jurisdiction [210.5(C)(1)(a)].

The

method of identification must be documented in a manner that’s readily

available or permanently posted at each branch-circuit panelboard

[210.5(C)(1)(b)].

method of identification must be documented in a manner that’s readily

available or permanently posted at each branch-circuit panelboard

[210.5(C)(1)(b)].

Author’s

Comment:

Comment:

When

a premises has more than one voltage system supplying branch circuits, the

ungrounded conductors must be identified by phase and system. This can be done

by permanently posting an identification legend that describes the method used,

such as color-coded marking tape or color-coded insulation.

a premises has more than one voltage system supplying branch circuits, the

ungrounded conductors must be identified by phase and system. This can be done

by permanently posting an identification legend that describes the method used,

such as color-coded marking tape or color-coded insulation.

Conductors

with insulation that’s green or green with one or more yellow stripes can’t be

used for an ungrounded or neutral conductor [250.119].

with insulation that’s green or green with one or more yellow stripes can’t be

used for an ungrounded or neutral conductor [250.119].

Although

the NEC doesn’t require a specific color code for ungrounded conductors,

electricians often use the following color system for power and lighting

conductor identification:

the NEC doesn’t require a specific color code for ungrounded conductors,

electricians often use the following color system for power and lighting

conductor identification:

§ 120/240V, single-phase—black, red, and white

§ 120/208V, three-phase—black, red, blue, and

white

white

§ 120/240V, three-phase—black, orange, blue, and

white

white

§ 277/480V, three-phase—brown, orange, yellow,

and gray; or, brown, purple, yellow, and gray

and gray; or, brown, purple, yellow, and gray

Power

conductors of alternating-current and direct-current systems rated 1,000V or

less can occupy the same raceway, cable, or enclosure if all conductors have an

insulation voltage rating not less than the maximum circuit voltage

[300.3(C)(1)].

conductors of alternating-current and direct-current systems rated 1,000V or

less can occupy the same raceway, cable, or enclosure if all conductors have an

insulation voltage rating not less than the maximum circuit voltage

[300.3(C)(1)].

Q3.

What are the rules related to the installation of conductors under 50V with

conductors from 120V, 208V, 240V, 277V, and 480V systems in the same raceway or

enclosure?

What are the rules related to the installation of conductors under 50V with

conductors from 120V, 208V, 240V, 277V, and 480V systems in the same raceway or

enclosure?

A3.

Class 1 circuit conductors can be installed with associated power conductors

[725.48(B)(1)] if all conductors have an insulation voltage rating not less

than the maximum circuit voltage [300.3(C)(1)].

Class 1 circuit conductors can be installed with associated power conductors

[725.48(B)(1)] if all conductors have an insulation voltage rating not less

than the maximum circuit voltage [300.3(C)(1)].

A

Class 2 circuit that’s been reclassified as a Class 1 circuit [725.130(A) Ex 2]

can be installed with associated power conductors [725.48(B)(1)] if all

conductors have an insulation voltage rating not less than the maximum circuit

voltage [300.3(C)(1)].

Class 2 circuit that’s been reclassified as a Class 1 circuit [725.130(A) Ex 2]

can be installed with associated power conductors [725.48(B)(1)] if all

conductors have an insulation voltage rating not less than the maximum circuit

voltage [300.3(C)(1)].

Note

2: PV system conductors, both direct current and alternating current, are

permitted to be installed in the same raceways, outlet and junction boxes, or

similar fittings with each other, but they must be kept entirely independent of

all other non-PV system wiring [690.31(B)].

2: PV system conductors, both direct current and alternating current, are

permitted to be installed in the same raceways, outlet and junction boxes, or

similar fittings with each other, but they must be kept entirely independent of

all other non-PV system wiring [690.31(B)].

Author’s

Comment:

Comment:

Control,

signal, and communications wiring must be separated from power and lighting

circuits so the higher-voltage conductors don’t accidentally energize the control,

signal, or communications wiring:

signal, and communications wiring must be separated from power and lighting

circuits so the higher-voltage conductors don’t accidentally energize the control,

signal, or communications wiring:

§ CATV Coaxial Cable, 820.133(A)

§ Class 1 control circuits, 725.48

§ Class 2 and Class 3 Control Circuits,

725.136(A)

725.136(A)

§ Communications Circuits, 800.133(A)(1)(c)

§ Fire Alarm Circuits, 760.136(A)

§ Instrumentation Tray Cable, 727.5

§ Sound Circuits, 640.9(C)

Q4.

What are the uses permitted and not permitted for flexible cords?

What are the uses permitted and not permitted for flexible cords?

A4.

Flexible cords and flexible cables within the scope of Article 400 can be used

for the following applications [400.7(A)]:

Flexible cords and flexible cables within the scope of Article 400 can be used

for the following applications [400.7(A)]:

(1)

Pendants [210.50(A) and 314.23(H)].

Pendants [210.50(A) and 314.23(H)].

Author’s

Comment:

Comment:

Only

cords identified for use as pendants in Table 400.4 may be used for pendants

[400.4].

cords identified for use as pendants in Table 400.4 may be used for pendants

[400.4].

(2)

Wiring of luminaires [410.24(A) and 410.62(B)].

Wiring of luminaires [410.24(A) and 410.62(B)].

(3)

Connection of portable luminaires, portable and mobile signs, or appliances.

Connection of portable luminaires, portable and mobile signs, or appliances.

(4)

Elevator cables.

Elevator cables.

(5)

Wiring of cranes and hoists.

Wiring of cranes and hoists.

(6)

Connection of utilization equipment to facilitate frequent interchange

[422.16].

Connection of utilization equipment to facilitate frequent interchange

[422.16].

(7)

Prevention of the transmission of noise or vibration [422.16].

Prevention of the transmission of noise or vibration [422.16].

(8)

Appliances where the fastening means and mechanical connections are

specifically designed to permit ready removal for maintenance and repair, and

the appliance is intended or identified for flexible cord connections.

Appliances where the fastening means and mechanical connections are

specifically designed to permit ready removal for maintenance and repair, and

the appliance is intended or identified for flexible cord connections.

(9)

Connection of moving parts.

Connection of moving parts.

Author’s

Comment:

Comment:

Flexible

cords and flexible cables are permitted for fixed permanent wiring by 501.10,

501.140, 502.10 502.140, 503.10, 503.140, 550.10(B), 553.7(B), and

555.13(A)(2).

cords and flexible cables are permitted for fixed permanent wiring by 501.10,

501.140, 502.10 502.140, 503.10, 503.140, 550.10(B), 553.7(B), and

555.13(A)(2).

Attachment

plugs are required for flexible cords used in any of the following applications

[400.7(B)]:

plugs are required for flexible cords used in any of the following applications

[400.7(B)]:

§ Portable luminaires, portable and mobile

signs, or appliances [400.7(A)(3)].

signs, or appliances [400.7(A)(3)].

§ Stationary equipment to facilitate its

frequent interchange [400.7(A)(6)].

frequent interchange [400.7(A)(6)].

§ Appliances specifically designed to permit

ready removal for maintenance and repair, and identified for flexible cord

connection [400.7(A)(8)].

ready removal for maintenance and repair, and identified for flexible cord

connection [400.7(A)(8)].

Author’s

Comment:

Comment:

An

attachment plug can serve as the disconnecting means for stationary appliances

[422.33] and room air conditioners [440.63].

attachment plug can serve as the disconnecting means for stationary appliances

[422.33] and room air conditioners [440.63].

Unless

specifically permitted in 400.7, the following uses are not permitted [400.8]:

specifically permitted in 400.7, the following uses are not permitted [400.8]:

(1)

Flexible cords must not be used as a substitute for the fixed wiring of a

structure.

Flexible cords must not be used as a substitute for the fixed wiring of a

structure.

(2)

Flexible cords must not be run through holes in walls, structural ceilings,

suspended or dropped ceilings, or floors.

Flexible cords must not be run through holes in walls, structural ceilings,

suspended or dropped ceilings, or floors.

Author’s

Comment:

Comment:

Article

400 requirements only apply to flexible cords [UL 62]; power supply cords [UL

817] don’t fall within the scope of Article 400, therefore a power supply cord

is permitted to run through a cabinet wall for an appliance.

400 requirements only apply to flexible cords [UL 62]; power supply cords [UL

817] don’t fall within the scope of Article 400, therefore a power supply cord

is permitted to run through a cabinet wall for an appliance.

(3)

Flexible cords must not be run through doorways, windows, or similar openings.

Flexible cords must not be run through doorways, windows, or similar openings.

(4)

Flexible cords must not be attached to building surfaces.

Flexible cords must not be attached to building surfaces.

(5)

Flexible cords must not be concealed by walls, floors, or ceilings, or located

above suspended or dropped ceilings.

Flexible cords must not be concealed by walls, floors, or ceilings, or located

above suspended or dropped ceilings.

Author’s

Comment:

Comment:

Flexible

cords are permitted under a raised floor (with removable panels) not used for

environmental air, because this area isn’t considered a concealed space. See

the definition of “Exposed” in Article 100.

cords are permitted under a raised floor (with removable panels) not used for

environmental air, because this area isn’t considered a concealed space. See

the definition of “Exposed” in Article 100.

Article

400 requirements only apply to flexible cords [UL 62]; power supply cords [UL

817] do not fall within the scope of Article 400, therefore a power supply cord

is permitted to run through or be located above a suspended ceiling.

400 requirements only apply to flexible cords [UL 62]; power supply cords [UL

817] do not fall within the scope of Article 400, therefore a power supply cord

is permitted to run through or be located above a suspended ceiling.

(6)

Flexible cords must not be installed in raceways, except as permitted by 400.14

for industrial establishments where the conditions of maintenance and

supervision ensure that only qualified persons will service the installation.

Flexible cords must not be installed in raceways, except as permitted by 400.14

for industrial establishments where the conditions of maintenance and

supervision ensure that only qualified persons will service the installation.

(7)

Flexible cords must not be subject to physical damage.

Flexible cords must not be subject to physical damage.

Author’s

Comment:

Comment:

Even

cords listed as “extra-hard usage” must not be used where subject to physical

damage.

cords listed as “extra-hard usage” must not be used where subject to physical

damage.

Q5.

What are the tap conductor requirements to supply household ranges,

wall-mounted ovens, and counter-mounted cooking units?

What are the tap conductor requirements to supply household ranges,

wall-mounted ovens, and counter-mounted cooking units?

A5.

Branch-circuit conductors that supply household ranges, wall-mounted ovens or

counter-mounted cooking units must have an ampacity not less than the rating of

the branch circuit, and not less than the maximum load to be served. For ranges

of 8¾ kW or more rating, the minimum branch-circuit ampere rating is 40A

[210.19(A)(3)].

Branch-circuit conductors that supply household ranges, wall-mounted ovens or

counter-mounted cooking units must have an ampacity not less than the rating of

the branch circuit, and not less than the maximum load to be served. For ranges

of 8¾ kW or more rating, the minimum branch-circuit ampere rating is 40A

[210.19(A)(3)].

Ex

1: Conductors tapped from a 50A branch circuit for electric ranges,

wall-mounted electric ovens and counter-mounted electric cooking units must

have an ampacity not less than 20A, and must have sufficient ampacity for the

load to be served. The taps must not be longer than necessary for servicing the

appliances.

1: Conductors tapped from a 50A branch circuit for electric ranges,

wall-mounted electric ovens and counter-mounted electric cooking units must

have an ampacity not less than 20A, and must have sufficient ampacity for the

load to be served. The taps must not be longer than necessary for servicing the

appliances.

Recent Posts

- The 13-Day Study Challenge: Mastering Electrical Exam Prep

- Navigating Commercial Service Calculations for the Texas Electrician Exam: Understanding Receptacle Load

- Connected Load vs. Demand Load for the Texas Electrician Exam

- Texas Electrician License Exam Prep: Garages and Basements in Load Calculations

- Mastering Three-Phase Transformer Calculations

Categories

- Business (2)

- Continuing Education CEU (1)

- Contractors (11)

- Exam prep (185)

- Excel in life (7)

- Formulas & Calculations (13)

- Health & Fitness (1)

- Newsletter (1)

- Resources (10)

- Sticky Note Reminder Series (2)

- Sticky Note Tip Series (23)

Related

Get Square for your business. Try it out here. Process $1,000 without fees when you activate with our link.